Flownex®

Flownex® Simulation Environment

Flownex® Simulation Environment (SE) delivers technology that enables you to study how flow and heat transfer systems will behave in the real world, where fluid is the driving factor. Flownex® SE system simulation relays the overall effect of changing specific properties on components, allowing you to extensively examine all possible variations in the design and optimization phases of systems.

Accelerate your system simulation with Flownex® SE

- Contact Us

Our Expertise Covers The Following Industrial Fields:

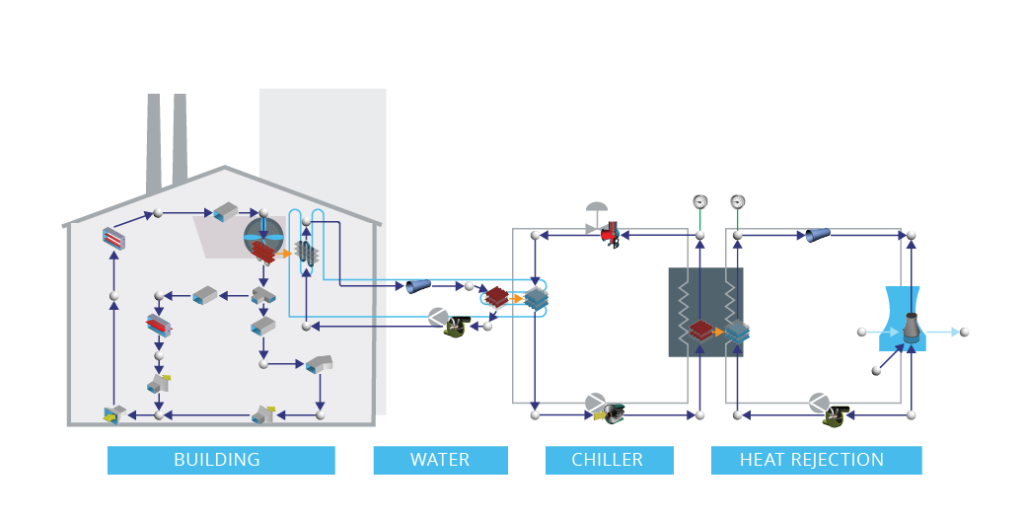

HVAC (Heating, Ventilation, and Air Conditioning)

Investigate into ducting design, refrigeration cycles with complicated refrigeration or costing calculations

Flownex® SE includes a comprehensive component library for analyzing large custom HVAC systems. This enables engineers to quantify conditions through the entire HVAC system in both steady state and transient operation. Furthermore, Flownex® SE contains the complex fluid models needed to simulate accident scenarios and help engineers prove the safety of their designs.

Applications

- Design and Optimize Advanced HVAC Systems

- Improve Overall Efficiency

- Investigate Risk and Perform Design Safety

- Features

HVAC SYSTEM

Oil & Gas

Perform integrated system analysis including design and modelling of pipe systems, valves, turbomachinery, and other oil and gas related applications.

Flownex SE provides the engineers the quick and robust way to deal with complex large hydraulic networks in steady-state and transient way. Design of gas distribution systems, sizing of valves and orifices, flow balancing, analysis of transient events are the basic application of Flownex SE.

Applications

- Drilling Mud Pumping Systems for Gas Wells

- Heat Exchangers

- Flares & Burners

- Turbomachinery

- Integrated System Analysis

- Fire Protection Systems

DRILLING MUD PUMPING SYSTEMS FOR GAS WELLS

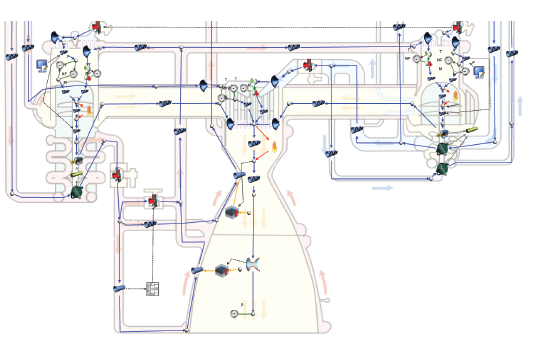

Aerospace & Defense

Flownex® SE can be utilized for modelling fuel and hydraulic systems, gas turbines and assists with the design of Environmental Control and Life Support Systems.

Applications

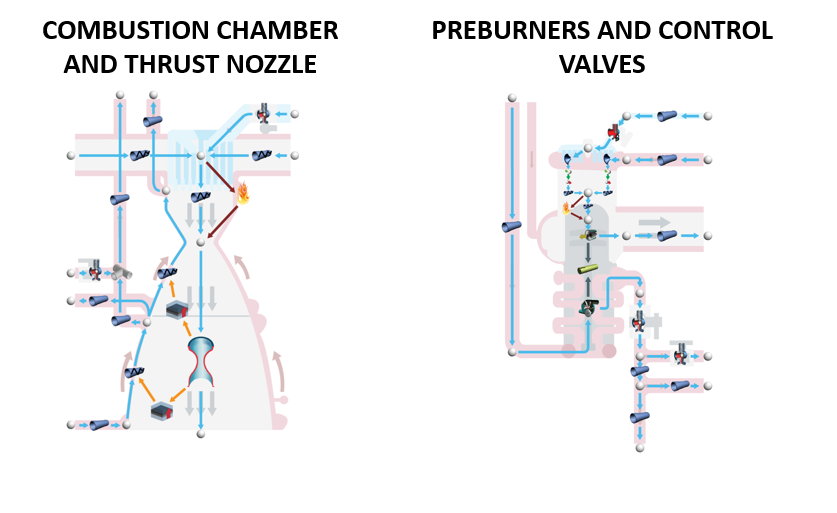

- Rocket Engines

- Environmental control & Life Support Systems

- Propulsion Systems

- Fuel & Refueling Systes

- Hydraulic Systems

- Liquid Fueled Rockets

ROCKET ENGINE

Nuclear

Gain a better understanding into the dynamic behavior of nuclear cycles

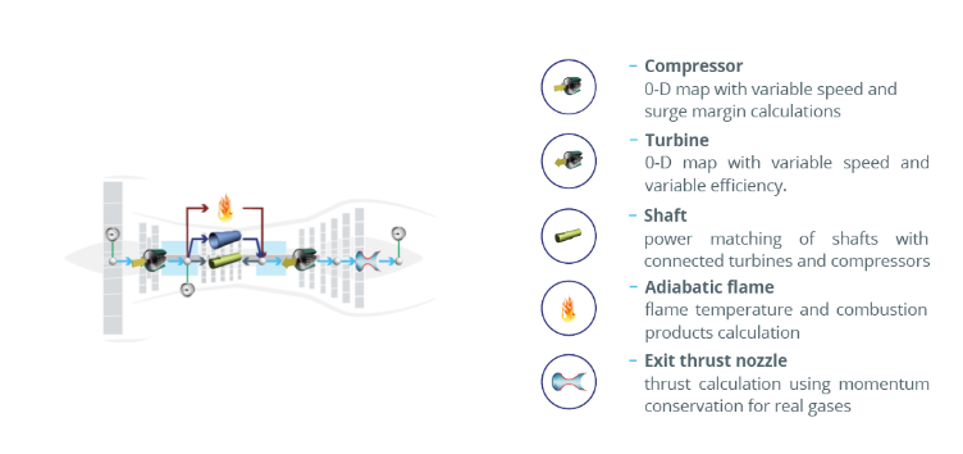

Gas Turbines

Model turbine secondary flow systems, combustion, flow and heat transfer.

Space Flight

Analyze the highly complex and interconnected components of space propulsion systems

Industrial Process

Minimise time-to-production and speed up commissioning by determining beforehand the energy consumption of a process.

Applications

- Cooling Water Systems

- Fire Propulsion Systems

- Heat Exchangers

- Integrated systems Analysis

- Slurries, Pastes & Non-Newtonian Fluids

- Hydraulic Systems

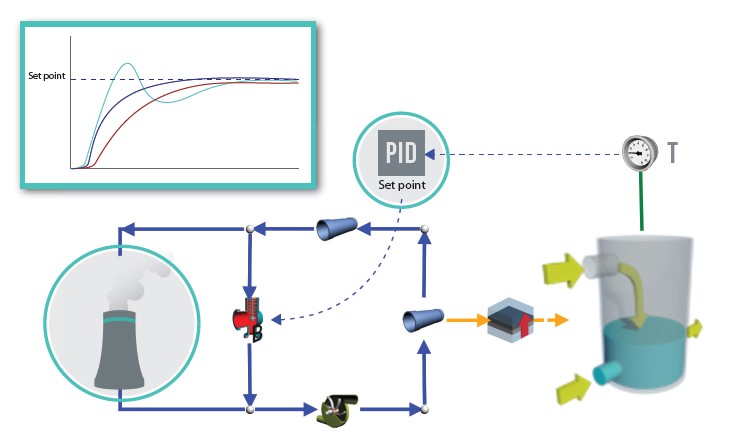

- Temperature Control Loop Design

- Steam Systems

- Flares & Burners

- And more

Academic

Solve fundamental physics of flow and heat transfer.

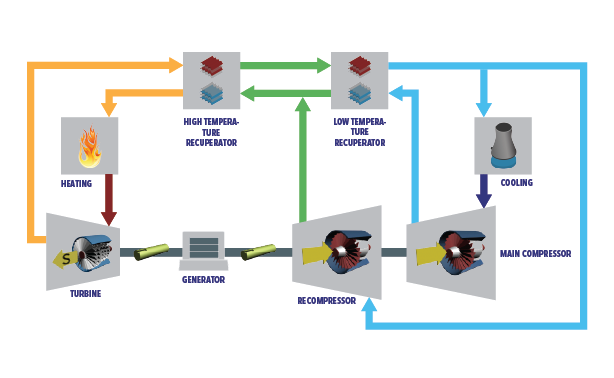

Supercritical Carbon Dioxide Power Cycle (sCO2)

Solve mass, momentum and energy in conjunction with two-phase fluid properties for system models.

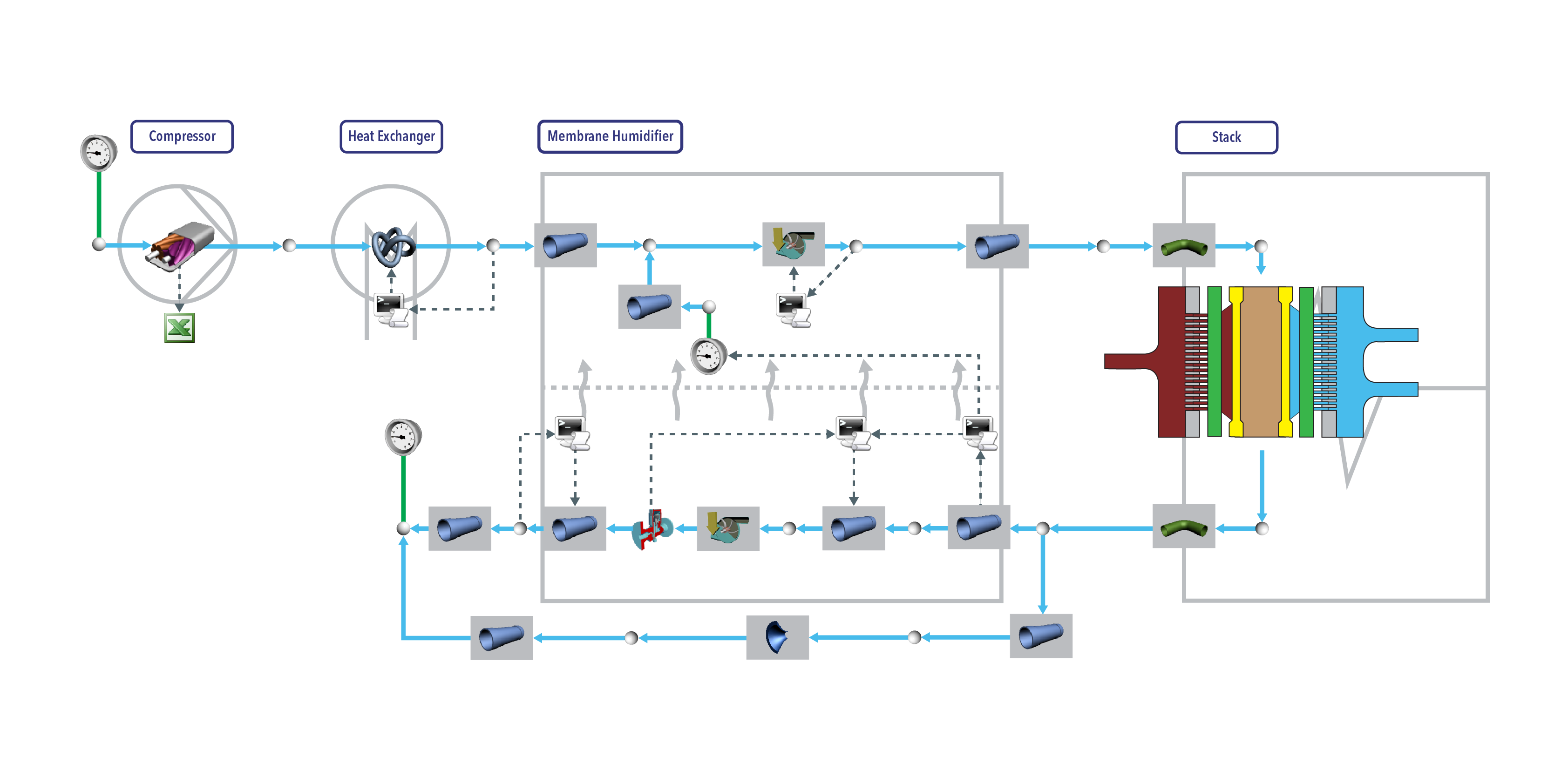

Hydrogen

Design and analysis of hydrogen applications: from fuel cells to the electrolysis of water.

With pressure on industries to move to zero emissions, a strong focus has been put on the research and development of hydrogen applications for decarbonization. The European Union, and others for example, want to get to net-zero greenhouse gas emissions by 2050. One way of doing this is to implement technologies such as hydrogen fuel cells to generate electricity. Green Hydrogen, where renewable energy is used to generate hydrogen from water using a process called electrolysis, is one of the main sources of carbon free energy currently being researched.

Applications

- Hydrogen Fuel Cells and System Components

- Proton-Exchange Membrane Fuel Cell Air Side

- Electrolysis of Water

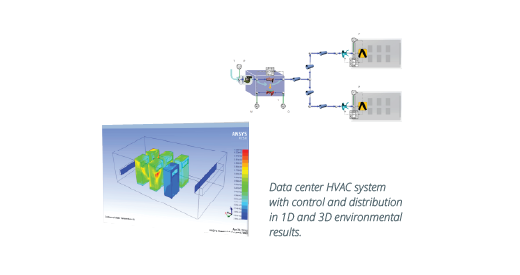

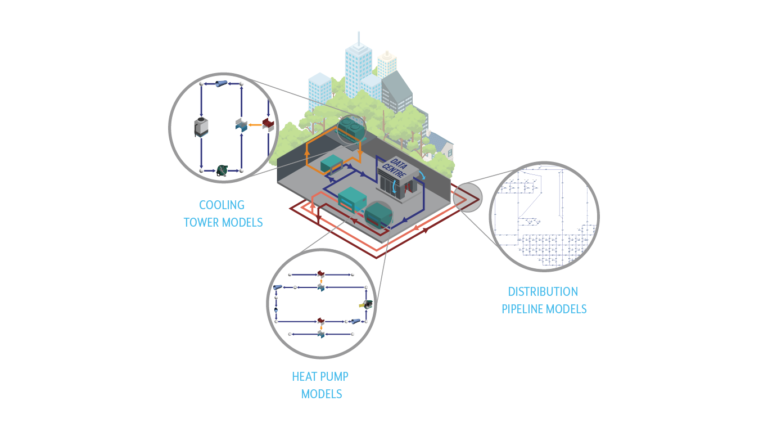

Data Centers

Design and evaluate flow and heat transfer systems by using advanced thermo-fluid modelling and co-simulation capabilities.

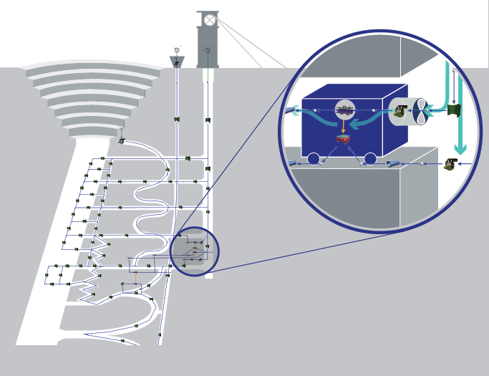

Mining

Flownex® SE has proved itself as an excellent tool in energy optimisation, slurry modelling, ventilation systems or any other mining-related system simulations.

Applications

- Backfill & Tailings Slurry

- Water Handling System Simulation

- Refrigeration & Heating System Simulation

- Ventilation

- Compressed Air Simulation

MINE VENTILATION

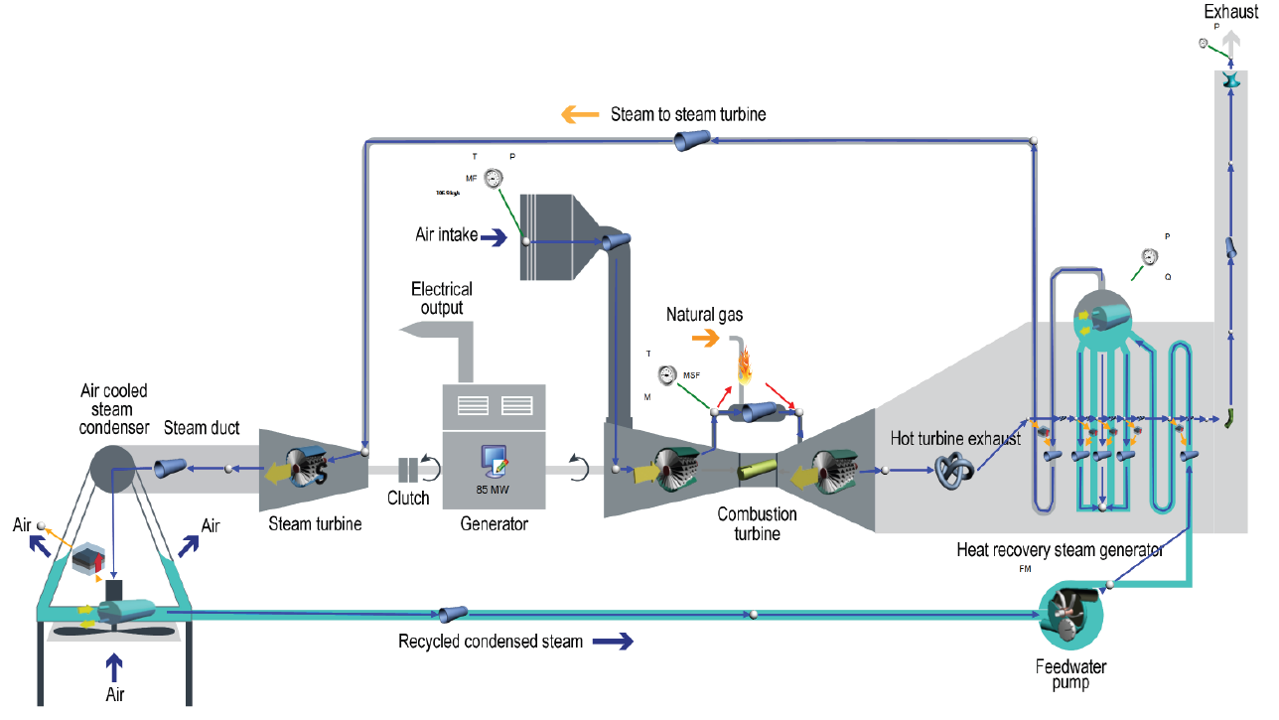

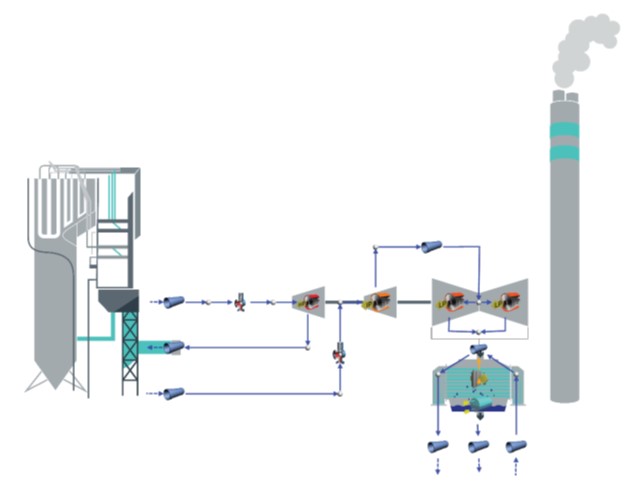

Fossil Fuel Power Generation

Optimise plant performance by modelling steam circuits, cooling water circuits, boilers, turbines, heat exchangers and other auxiliary plant systems.

Applications

- Feedwater Systems

- Cooling Water Circuits

- Steam Turbine & Supporting Systems

- Boiler Steam Systems

- Ash Slurry

- Natural Circulation Boiler

- Condensers

- Combined Cycle Plant

- Boiler Auxiliary Systems

COMBINED CYCLE PLANT

Overview

Flownex® SE determines the pressure drop and heat transfer of interconnected components in a complete system both in steady state or transient simulations.

Flownex® SE is developed within an ISO 9001:2015 quality management system that is ASME NQA-1 compliant.

Analysis:

- Unit digital twins

- Safety analyses

- Fault root-cause analysis

- Performance calculations

- Thermo-hydraulic and thermodynamic analyses

Design:

- Design verification

- Component and system sizing

- Determine operating ranges

- Design for energy efficiency

- Test control philosophy

Optimization:

- Optimize performance

- Control system tuning

- Predict system transient behavior

- Parametric studies and sensitivity analysis

FOSSIL FUEL POWER STATION

Basic Thermal Fluid Models

This module includes the ability to simulate both liquids and gasses, adiabatic flows, as well as flows with basic heat transfer in steady-state approach. The flow component models included in the basic version are reservoirs, pipes, ducts, pumps, fans, compressors, turbines, heat exchangers, valves and orifices. This module allows to use numerous visualisation components, graphs, text outputs, result layers, data logging, and Excel result exports, as well as the ability to create compound components.

Advanced Fluid Thermal Module

This configuration includes advanced features such as gas mixtures, homogeneous two-phase flow, coupled convective and conductive heat transfer through solid structures as well as a special library of rotating components used in the design of turbomachinery. It also includes combustion modelling, Script elements for custom functionality and the built-in Excel workbook component.

Design & Analysis Module

This configuration includes advanced analysis features such as the designer routine, optimization routines, and stochastic routines used in probabilistic analyses (Sensitivity Analyses, Parametric Studies).

Transient Module

This module allows:

- Start simulations from either steady-state calculate or specified initial conditions;

- Open loop events can be specified at different time steps (time varying or fixed variables, switching system controllers on or off);

- Graph values of multiple parameters over time on the screen whilst solving.

TEMPERATURE CONTROL LOOP DESIGN

Flownex® SE & Ansys Co-Simulation

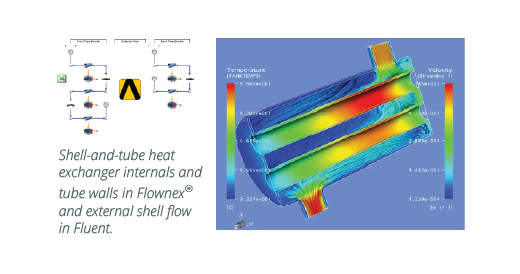

Flownex® SE is able to couple to a range of Ansys products which opens a new frontier in co-simulation. This gives users the ability to simulate complete and integrated engineering systems quickly and accurately.

State of the art fluid models in Flownex® SE can accurately model 1D flow and 2D heat transfer. This can be used to replace 1D flow in 3D flow simulations: in doing so mesh sizes can be reduced and solving times can be drastically decreased. Flownex® SE contains component models ideal for modeling large, interconnected systems and can be coupled to 3D simulations to transfer the change in component performance to a change in overall system performance.

Examples:

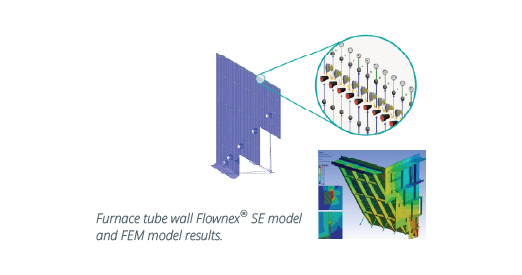

- Transient Thermal Stresses – Effect Of Start-up & Dynamic Load Changes

- Simplified Heat Exchanger – Model Complex External Geometry With 3d Whilst Modelling The Internal Flow With 1d Simulation

- Long Tranisients – Coupled Flow Simulations