AI and ML: The Brave New World of Simulation

Artificial intelligence and machine learning are affecting just about every part of our professional and personal lives — and engineering simulation is no exception.

While the concepts of artificial intelligence and machine learning used to sound like the stuff of science fiction, today they’re becoming ubiquitous ― and there’s little doubt that they’re making our lives better. From earlier disease detection and assisted driving to warehouse optimization, production lines and other jobsites, artificial intelligence (AI) and machine learning (ML) are helping to make us healthier, safer, and more productive.

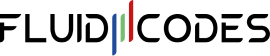

Because there seems to be no limit to the capabilities of AI and ML, it should come as no surprise that they are also quietly changing the field of engineering simulation. Recently, Ansys has been collaborating with global thought leaders in AI and ML in an effort to make Ansys’ best-in-class tools even better.

For instance, Director of Software Development Jay Pathak is leading a team of Ansys researchers who recently co-authored a paper with Stanford University on how machine learning might be applied to represent geometries in a manner that is suitable for learning partial differential equations used in various Ansys solvers. Lightweight geometry representation is the starting point for any machine learning closer to the solver’s realm.

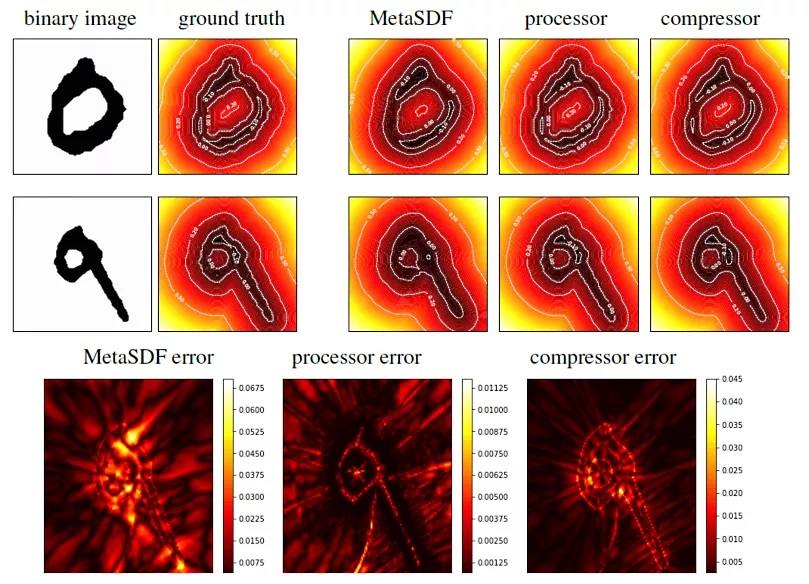

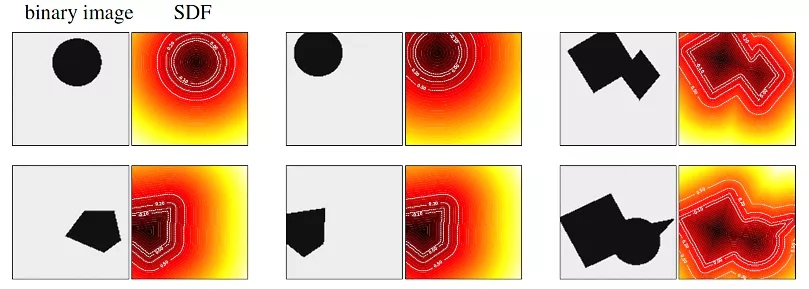

Capitalizing on convolution neural networks, the Ansys-Stanford team is leveraging new, data-driven, and physics-informed machine-learning models that could allow computer-aided design (CAD) engines to quickly represent simple shapes via a new geometry encoding process. The new, lighter-weight encoding process results in a compressed spatial representation that still produces numerically accurate results.

Ultimately, Pathak and his team are working to make the geometric understanding of Ansys smarter and more autonomous, able to intuitively mix lightweight and heavier-weight representations of 2D and 3D objects, as needed, to solve every customer problem. “We’re always trying to find that ‘sweet spot’ between solution accuracy and speed,” Pathak adds. “It’s exciting that machine-learning capabilities might be the key to our software identifying the right balance for every customer problem.”

Leveraging AI and ML to Create Lighter-Weight Geometric Representations

“I think we all understand that AI and ML can solve extremely large, numerically intensive, complex problems in computer vision and natural language processing and so excited about applying it for learning physics which in many ways is similar,” says Pathak. “They have an unmatched ability to ingest enormous volumes of data while in training mode and arrive at statistically accurate answers in deployment mode, in milliseconds. Sometimes some of these simulations would take humans weeks or even months to finish.”

Pathak points out that machine learning can complement technology tools, like simulation software. “Machine-learning tools can be applied to classify geometries, identify part connections, and work as a recommender system to decide next steps while working with geometric parts and assemblies or setting up simulation problems in Ansys products. This will be big step in customer usability and productivity,” notes Pathak.

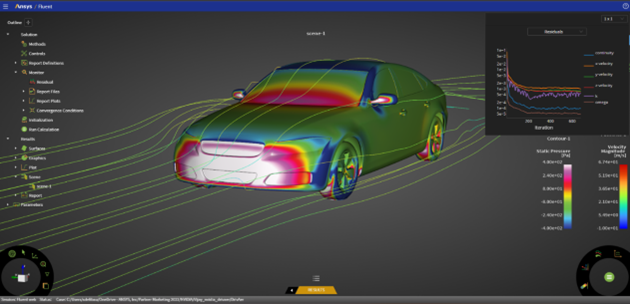

“The recent paper co-authored with Stanford focuses improving the state of the art in representing geometries in a manner that will be suitable for learning physics down the line. We have shown strong generalization of our model including verification from other public datasets. The model, although trained with simple parts (such as sphere, cylinder, or prims) and unions or intersections with other similar parts, generalizes to complex parts used by Ansys customers such as engines, turbines, etc.,” Pathak states. “Instead of relying solely on human software developers to advance the state-of-the-art of engineering simulation, we’re exploring the potential of machine learning to complement our traditional software development efforts.”

How can AI and ML help? According to Pathak, by identifying repeating patterns in geometries machine learning can encode only relevant information and hence allow a decent level of compression to represent geometries. A trained model can be used to decode back this representation when needed into full-fledged 3D or 2D geometries.

“One of the biggest challenges in machine learning is generalization, such as how the trained model behaves when it is challenged with a new complex geometry that it never saw during training. We had to ensure that during training time, we have enough of a geometric shape covered, at just enough level of fidelity, to generate a lightweight yet accurate representation,” Pathak explains. “We want to make sure our model has seen large variabilities in geometries with a goal to ensure the model is data efficient. Otherwise, we run the risk of long and slow training times.”

“Machine-learning tools can be applied to classify geometries, identify part connections, and work as a recommender system to decide next steps while working with geometric parts and assemblies or setting up simulation problems in Ansys products. This will be big step in customer usability and productivity.”

— Jay Pathak, Director of Software Development, Ansys

Looking to the Future

The application of AI and ML is still in its relative infancy, and its full potential for making simulations faster, smarter, and more accurate has yet to be seen. But Pathak emphasizes that the software development team at Ansys is committed to contributing to AI advances that will one day make this brave new world of simulation a reality for Ansys customers worldwide.

The broad adoption of AI and ML is having enormous implications for the performance of many products ― and incorporating this advanced technology is making the job of product development teams more complex and challenging than ever, according to Pathak.

At the same time, Ansys is capitalizing on those same AI and ML capabilities to help customers solve their most complex problems. “We’re starting with the task of geometric representation, because that’s a foundational problem that affects virtually every engineering team. But there’s no limit to other applications of ML such as in solving physics, meshing, identifying different domains etc.

For everyone in our industry, it’s an exciting time, and I think we’re only at the beginning of realizing the potential of artificial intelligence and machine learning to change the world as we know it — including the capabilities of simulation software.