Designing the James Webb Space Telescope with Simulation

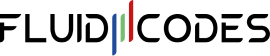

NASA has once again embarked on a mission to transform our understanding of the universe on December 25, 2021. For decades, the NASA Hubble Space Telescope has provided awe-inspiring images of distant galaxies, nebulae, and stars. However, the James Webb Space Telescope (JWST) may provide an extraordinary leap in our understanding of the universe. With a primary mirror capable of collecting six times more light than Hubble and longer image wavelengths, JWST will enable scientists to look back in time at the earliest formations of the universe.

James Webb Space Telescope Design Requirements

JWST requires pioneering technology not only to get into space, but see what has never been seen before. The telescope has the largest and most precise optical instrument ever built; one that is designed to stay extremely cold — nearly minus 400 degrees Fahrenheit or minus 240 degrees Celsius.

Engineers had to create a structure that can:

- Operate in perpetual solar radiation

- Fold a structure the size of a tennis court into a rocket

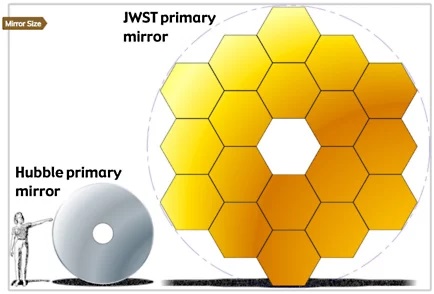

- Fly over a million miles into space

- Remotely unfold dozens of mechanisms in an intricate mechanically orchestrated ballet

Simple, right?

If any of these delicate maneuvers fail, the mission will be a loss. With 344 “single-point failures,” JWST is one of the riskiest missions in history.

Mitigating Risk with Pervasive Engineering Simulation

Because the JWST is entirely too large to test everything in person, and testing on Earth isn’t the same as testing in space, engineers simulated how the telescope will act in its operational environment. Northrop Grumman is the prime contractor that designed and built the JWST and simulation played a critical role in that process. “You design it, you build it, you design a computer model to imitate it,” said Scott Willoughby, Vice President of the James Webb Space Telescope at Northrop Grumman Space Systems. As the world’s leading provider of engineering simulation tools, Ansys is proud to have supported this mission.

DRM, Orbit Determination, and SRP

Engineers used Systems Tool Kit’s (STK) Astrogator capability from AGI, an Ansys company, to build complex design reference missions (DRMs). These account for the complex gravitational perturbations in libration-point (L2) orbits to estimate station-keeping requirements. They will also use AGI’s Orbit Determination Tool Kit (ODTK) to perform operational orbit determinations. To model the pressure of the light from the Sun on the large Sun shield deployed on JWST, they used the custom solar radiation pressure (SRP) plugin point in ODTK to insert a proprietary model into ODTK’s advanced estimation algorithms.

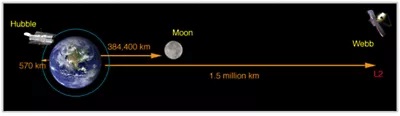

Mirror Pointing

Engineers used Ansys Mechanical simulations to identify solutions to the precise mirror pointing given the natural vibrational frequencies of the structures. Mechanical helped determine the effects of having a connected, segmented mirror. The goal is for the segments to respond to disturbances the same way a monolithic mirror would.

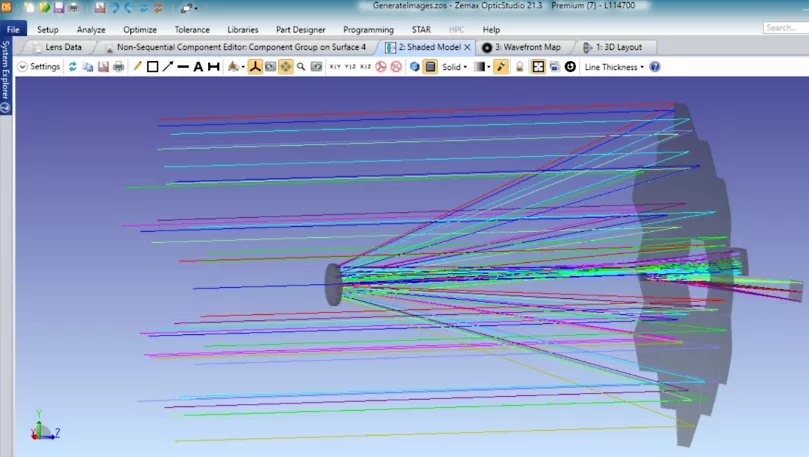

Mirror Alignment

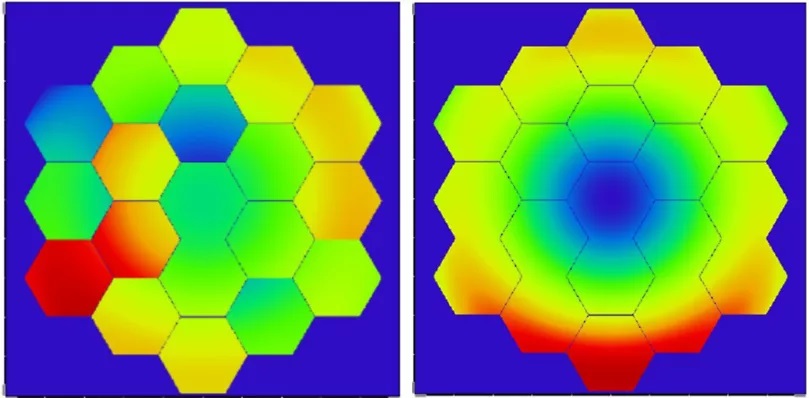

Ansys Zemax software simulated the complex optics of the numerous individual gold-plated mirror segments in the telescope. The 18 hexagonal segments of JWST’s primary mirror must function as a single mirror, with a surface smoother than 100 nanometers. Engineers used Zemax software to design and test every step of the alignment process, from the initial segment search to the final Fine Phasing.

They designed a unique “Coarse Phasing” step that analyzes spectra to correct piston errors — a segment that is too far forward or behind the others — between the segments. Zemax models were also used to design the multifield step, the final check of the alignment. By building a physical test bed of the telescope — one-seventh the real size — engineers used Zemax to simulate each alignment step before running the alignment in real hardware. Flight models then translated the test bed telescope to the real alignment situation that will occur on-orbit. Flight models in Zemax generated statistical models that could predict the most likely state of the primary mirror at each step in the alignment process to support the design of the segment actuators and to predict when other onboard instruments will receive useful information.

Due to the size of JWST, gravity when testing on the ground, and JWST’s passive cooling system, simulations of all kinds were stretched to the limits of their accuracy during the development of the telescope. Ground-based testing verified the pieces of the simulations that could be directly tested, and the verified models then predicted the on-orbit behavior of the observatory. Once in orbit, data from the observatory will perform final verifications of many of the models. Ansys software users are designing the technology of the future, and Ansys wishes the JWST team the best of luck in their amazing mission to understand the universe.