Top 6 New Ansys Fluent Features in 2021

Our goal at Ansys is to continuously improve all our engineering simulation products to keep up with the ever-changing needs of our customers. We accomplish this goal by paying attention to developments across all industries, listening to our customers’ needs, and constantly innovating solutions to help engineers overcome their greatest challenges. Over the past year, we have made many improvements in Ansys Fluent, but we wanted to highlight the top six features, which includes:

1. A new Pro capability level

2.New multiphase modeling techniques

3.Best practices for dynamic mesh adaption

4.Combustion enhancements to push for decarbonization

5.New high-speed flow modeling capabilities

6.Productivity improvements

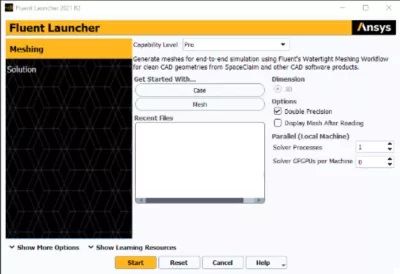

Access Fluent at an Attractive Price

Many computational fluid dynamics (CFD) engineers rely on Fluent’s industry-leading performance and accuracy, but typically work on applications that don’t require the full range of physics capabilities available in Fluent.

Fluent has a Capability Level drop-down menu on the Fluent Launcher, which used to have only Premium and Enterprise options available. But now, Pro has been added as a new option. Pro is a new capability level that tailors Fluent’s user-friendly interface for CFD applications that don’t require the full range of physics.

The Pro level still gives you access to many of Fluent’s industry-leading features and capabilities, including:

- The powerful task-based Watertight Meshing Workflow that creates high-quality Mosaic Poly-Hexcore meshes.

- Advanced solver technology with support for simulation of turbulent steady-state flows of single-phase fluids with conjugate heat transfer.

- Expressions support that makes it easy to implement spatial- or solution-dependent boundary conditions.

All the powerful and interactive post-processing and visualization capabilities.

Efficiently Simulate Breakup, Pooling, and Thinning of Multiphase Flows

In many applications with sprays and free-surface flows, keeping the simulation both accurate and practical requires adapting the modeling methodology throughout the domain based on the flow characteristics.

- For nearly spherical droplets, Fluent’s discrete phase model (DPM) provides an efficient method for tracking droplet trajectories and breakup/coalescence without highly resolved mesh requirements.

- Thin films on walls are best modeled using Lagrangian or Eulerian wall film models.

- Intricate free surface flows and thick films/pools require the interface tracking capabilities of the volume of fluid (VOF) method, with attendant highly resolved meshes.

https://youtu.be/ooDLYw_AyuI A given problem will often require trading off among these modeling techniques to optimize the simulation’s accuracy and efficiency. With the latest release features, Fluent now allows the combination of these various approaches, so you can automatically switch between the appropriate method depending on the local conditions (droplet asphericity, film height, etc.).

These new modeling techniques can be used with Fluent’s polyhedral unstructured mesh adaption (PUMA) method, so the volume mesh can be automatically refined and coarsened as needed.

Accelerate Fluent Simulations with Mesh Adaption

Dynamic mesh adaption is a method of refining the mesh of a simulation during the solution based on the solution itself. This scheme in Fluent enables you to start from a coarse mesh and dynamically refine high-gradient regions.

Dynamic mesh adaption can be used in combination with the PUMA method. PUMA does not rely on templates for refinement, so it works on all cell types. A mesh can also be coarsened after it has been refined.

In the latest releases, best practices for combustion and multiphase applications have been embedded in Ansys Fluent’s mesh adaption setup panel as pre-defined recipes requiring minimal user input, resulting in:

- Up to 70% cell count reductions

- Up to 4X speed ups for steady state cases

Mesh adaption for combustion cases has been shown to reduce cell count by up to 70%.

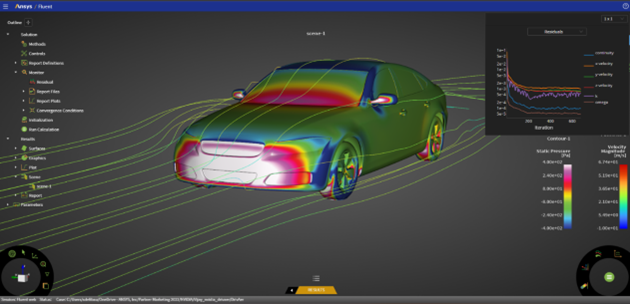

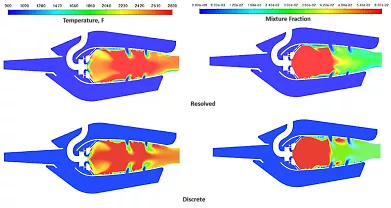

Combustion Enhancements for Decarbonization

Major combustion enhancements have been made this year, outside of the mesh adaption best practices for combustion applications. Some of these enhancements include a perforated wall model, validated hydrogen combustion models, and a strained flamelet generated manifold (FGM) model.

The perforated wall model enables you to simulate flow from many small holes through a solid region by modeling the holes rather than fully resolving them in the mesh. This reduces cell count and computational time. This feature could be valuable in the early stages of gas turbine combustor design when effusion cooling arrangements on the combustion liner need to be simulated, but it is impractical to simulate the finest details of all candidate designs.

Accurately and Efficiently Solve High Speed Flows

At hypersonic speed, fluids start to exhibit complex physical behaviors that are challenging to replicate accurately using experiments and flight tests. In this context, high-fidelity simulation becomes a key-enabling technology for the design and analysis of hypersonic vehicles. Some of the key phenomena that occur include strong shocks, plasma, ablation, structural deformation, and chemical non-equilibrium. To capture these phenomena accurately and efficiently, we have been dedicated to making major improvements in the workflow, physics modeling capabilities, and solver numerics.

As objects begin to travel faster than Mach 5, strong shock gradients begin to occur and can pose difficulties in the numerical simulation, leading to slow convergence and/or unphysical solutions. To help accurately capture these shocks, we introduced new adaptive numerics to the density-based solver that can robustly solve and capture shocks in flows as high as Mach 20. For flows of Mach 30 and above, improved treatment of reaction sources in the density-based solver has resulted in speed ups of up to 5X. These enhancements can be combined with some of the new physics capabilities to generate extremely robust and accurate results.

Some physics capabilities Fluent has offered through user-defined functions or the text user interface have now been built into the interface, and many brand-new capabilities have been introduced, including:

-A new built-in thermodynamic non-equilibrium capability using a two-temperature model

-A built-in workflow for wall recession to model surface ablation that leverages dynamic mesh

-NASA-9 coefficient curve fits for material properties

-Partial slip-wall model for rarified flows

Building these physics capabilities directly into the Fluent graphical user interface (GUI) is one of the many steps we are taking to streamline high-speed aerodynamics simulations. To streamline and automate the whole workflow from meshing to post-processing, we will be releasing a brand-new workspace in our next release, 2022 R1. Stay tuned to learn about the new Fluent Aero workspace that automates the creation of parametric flight conditions and uses Fluent’s latest solver and convergence advancements for these applications.

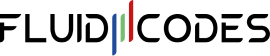

Increased Productivity for Every Engineer

With each release, our goal is to continue to improve productivity for the engineers who use our software. This year, we have made enhancements from reducing the time to read in a case file all the way to introducing a streamlined workflow to analyze and listen to acoustic pressure signals from your CFD simulation.

Some of the productivity and usability enhancements all users can benefit from include:

- Automated creation of simulation reports to generate a PDF or HTML of data visualization with monitors or graphs embedded in a single tab

- Addition of more color maps, improved lighting behavior and rendering of solid materials

- -Immediate reporting of post-processing values with interactive probe capabilities

- -10X speed ups for reading in large case files with thousands of zones

- -Automated graphics de-featuring while rotating or zooming over a model to improve interactivity

- -Advanced pattern meshing with rotation and translation capabilities for applications like batteries

- -A streamlined solution for acoustic pressure signal analysis directly inside Fluent using the advanced acoustics analysis techniques of Ansys VRXPERIENCE Sound