What is Digital Mission Planning?

The pressure was on, and the design engineers at an American aerospace giant needed a new approach to developing products. While the traditional approach — design, build, test, and repeat — had won them a long string of successes, times have changed. Indeed, their entire company was in the midst of an enterprise-wide digital transformation to respond to the new reality: products must get to market faster. Against this backdrop, the team of engineers decided to use simulation to achieve a much leaner approach: model, analyze, then build.

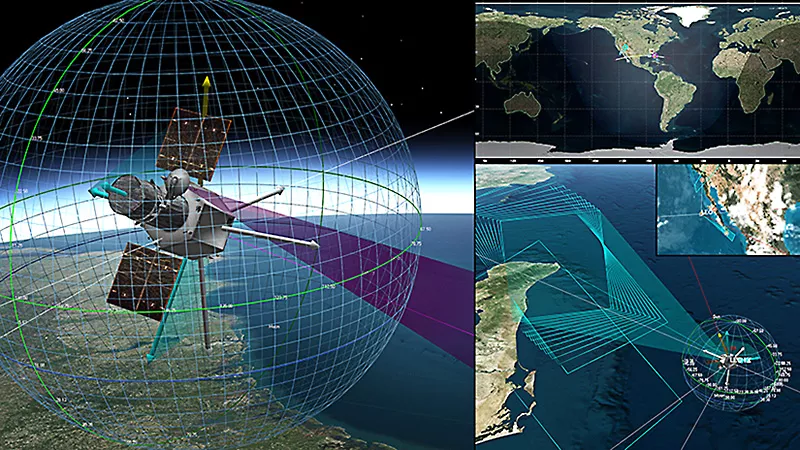

One essential element of this new approach was digital mission engineering — pioneered by AGI, now Ansys Government Initiatives. Digital mission engineering is the use of digital modeling, physics-based simulation, and analysis to incorporate the operational environment and evaluate mission outcomes and effectiveness at every phase of the life cycle. In other words, you simulate your product in a digital model of the conditions it must operate under and evaluate how well it will perform.

Digital Mission Planning

How did digital mission engineering assist with this team’s project? The team needed to optimize an airborne communications gateway, to be used by a variety of warfighters. This gateway would comprise radios and antennas — some under wings, others on the fuselage — plus data links and voice systems.

The challenges were significant, starting with the millions of channel combinations to analyze and solve. Complicating this analysis were environmental factors such as co-site interference from the emitters and antennas sharing such a limited space. And, beyond the gateway’s potential to hinder itself, the entire electromagnetic (EM) spectrum is an increasingly congested and contested domain.

Applying digital mission engineering, the team simulated the gateway by performing a variety of expected missions in a model of its operating environment. They analyzed the data from these simulations to understand interference on the gateway, effectively allocate the channels to be used, and determine antenna placement and pattern. Because these tests were simulated, the cycles of adjustment and reevaluation were only waiting on new data — not new prototypes.

The result? The engineers achieved their goal in about half the time it usually took. Let’s take a closer look at how they did it.

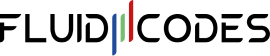

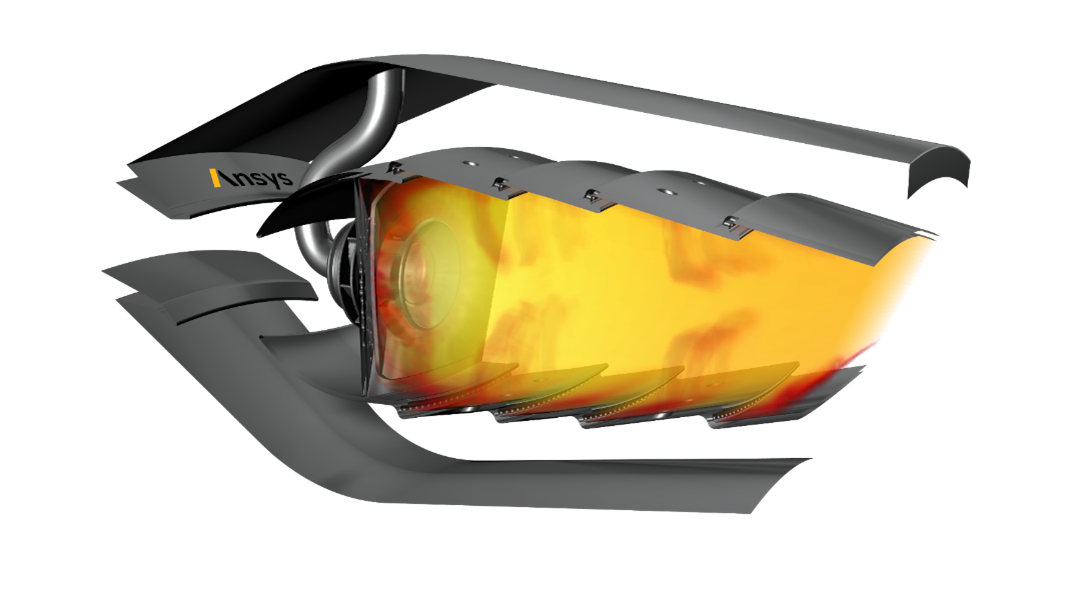

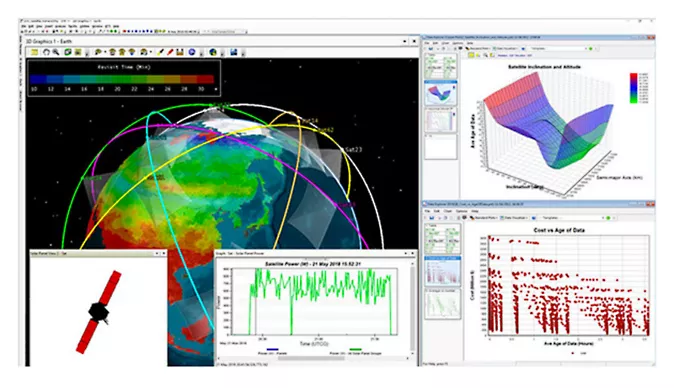

The process began with designing a mission model in Ansys Systems Tool Kit (STK) that represented the gateway’s operational environment — what it needed to do, but also where and when. This enabled them to evaluate their designs to understand how real-world variables might affect them, and why, from the beginning.

The next step was to integrate Ansys HFSS (3D, high-frequency simulation) with STK to determine a link budget, which measures the total transmitted power in a radio system, including all gains and losses. Now the team could use its arsenal of simulation tools to optimize the gateway design, while gaining important insights about how each change would impact mission success with just a few clicks. Here are some of the ways that they applied simulation solutions and their mission model to the challenges they faced:

- Importing computer-aided design (CAD) geometry files of aircraft that would host the gateway into HFSS to create nominal antenna designs, understand the installed electrical response at various locations, and then pick the right spots and pattern for the antennas.

- Exporting the information from HFSS into Ansys Emit, which predicts interference in a complex system comprising multiple emitters that operate simultaneously. The results of this analysis indicated which channels or radios would have a destructive effect on avionics or other systems and services.

- Mitigating co-site interference by filtering and using frequency planning to reallocate the channels and antennas, then applying the changes to the analysis in HFSS.

- Importing the antenna response as installed, and the selection of clean channels, into STK. This enabled engineers to visualize the effects of all of the components on the whole gateway while they simulated various maneuvers and routes.

Faster, Smarter, Better Mission Planning

Through digital mission engineering, the engineering team could quickly understand the performance of their gateway and identify new requirements, without physical testing. The rapid iterations of modeling and analysis dramatically accelerated the project’s timeline and enabled the team to deliver a first build that was closer to production-ready than legacy approaches could achieve. In a world where time to market is a crucial discriminator, digital mission engineering provides an unparalleled advantage.

The Meaning of Mission

One of the trickier things to contend with is a simple question, one that you assume you know the answer to until you ask it: What do we mean when we say “the mission”? The reason it’s not so simple is that people use the word mission in many ways. So, what do we mean when we talk about the mission in terms of digital mission engineering? Let’s break it down.

A mission is:

- The things that a product, system, or platform is supposed to be able to do

- The environment it must do it in — including natural forces and competitive or adversarial activity

What are some examples of this kind of mission?

At the simplest, you might say that a spoon is supposed to enable you to eat soup, and a bowl of soup would then be its operational environment. Or consider a heat pump for your home, which must be able to heat and cool it. A heat pump’s environment includes many factors, from weather outside the house to airflow inside it.

A mission can have conditions, too, like a car that must be able to safely transport four to six human passengers and some amount of cargo while averaging a certain fuel efficiency, and so on. If you’ve driven a car, then you’re already very familiar with how dynamic that environment can be, and how those dynamic factors can affect the car’s mission conditions in different ways.

Finally, consider a radar that detects aircraft, which someone else may not want it to do. There’s a good chance that its environment includes competitive or adversarial activity — for example, an aircraft that’s trying to jam it.

So, while the definition of mission can be distilled reasonably simply, the full expression of a particular mission can be multifaceted and intricate. And as you can imagine, the more complex the mission, the greater the advantage you gain from digital mission engineering.

Diversifying Missions

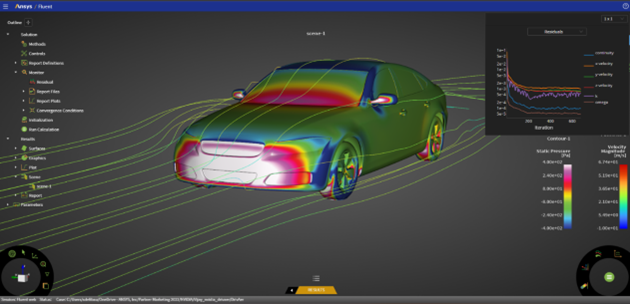

Digital mission engineering was first implemented in the aerospace industry, and its use there continues to spread. At the same time, Ansys — and our customers — are proving that the same approach can be successfully applied to a diverse set of other systems, including automotive vehicles, maritime vessels, and smart cities.

Let’s look at an example of how digital mission engineering could apply to another industry: telecommunications. You might say that a cell phone’s mission is to maintain data rates, links, and voice communication anywhere within a crowded urban environment. You have defined the things it must do and the environment it must do it in. In what ways could digital mission engineering provide insight into this phone’s ability to perform its mission? Here are a few things you could analyze:

- Dynamic environmental factors, such as natural radio frequency (RF) interference on complex communications networks

- System-of-systems interactions, such as taking a picture while streaming a video conference call, while connected to a Bluetooth headset

- How motion affects performance. For example, a phone may rely on positioning information from GPS satellites, so it is important to consider how obstructions such as buildings vary as the device travels through a city.

Obviously, we’re keeping things simple here. But once you understand the full meaning of mission in the context of digital mission engineering, you can begin to appreciate the multitude of applications waiting to be realized.

Properly applied, digital mission engineering increases efficiency and reduces costs, starting from the very beginning of product design and carrying all the way through to operations and maintenance. And by continuously validating real-world performance as you advance through the life cycle, you start each new phase with confidence that your design is ready for that next step. Moreover, once you see, firsthand, how efficient the approach makes your team, you can start to consider truly extraordinary leaps in innovation.